Magna tal-Qtugħ CNC ta' Kwalità Għolja

1. Il-qafas kollu tal-magna huwa pproċessat miċ-ċentru tal-ipproċessar tal-pentaedru SHW tal-Ġermanja f'ħin wieħed.

4. L-angolu tat-tqattigħ jista' jiġi aġġustat faċilment permezz tal-ipprogrammar biex tiġi evitata d-deformazzjoni tal-biċċa tax-xogħol ikkawżata mit-tqattigħ.

5. It-tul tal-puplesija tar-raġġ ta' fuq jista' jiġi aġġustat awtomatikament biex jinkiseb qtugħ veloċi u preċiż ta' biċċa tax-xogħol qasira u żgħira sabiex tittejjeb l-effiċjenza tax-xogħol.

6. Is-sistema CNC taġġusta awtomatikament id-distakk tax-xfafar skont il-ħxuna u l-materjal differenti tal-folja biex ittejjeb il-kwalità tat-tqattigħ.

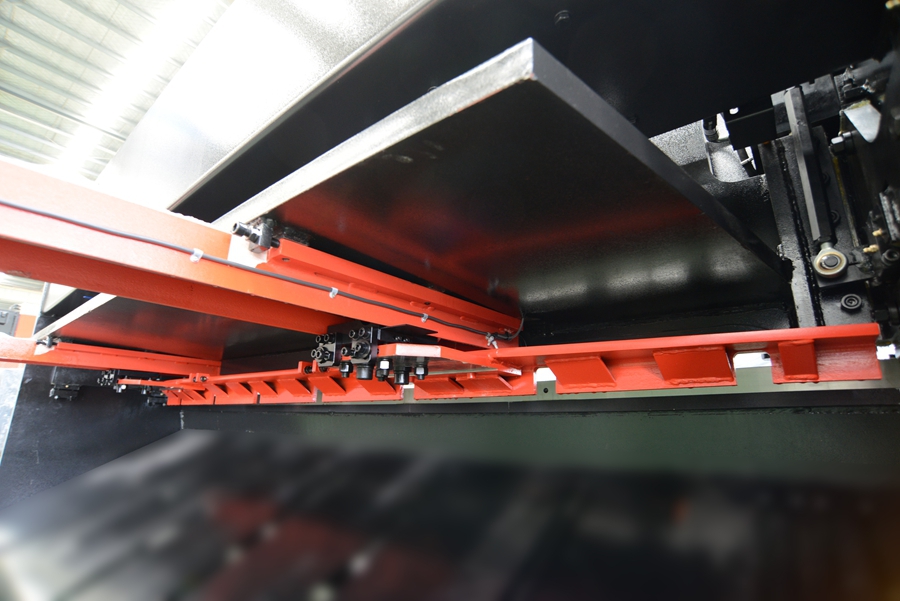

7. Xafra tal-qtugħ b'erba' naħat hija adottata biex ittejjeb il-ħajja tas-servizz tax-xafra li hija ħafna aħjar minn dik tal-shear li jitbandal.

8. Disinn ġdid ta' backgauge, struttura stabbli, ittejjeb ir-reżistenza għall-ilbies, il-ħbit ħafna

2. Jadotta s-sistema CNC Delem DAC360:

● Kontroll preċiż tal-backgauge

●kontroll preċiż tal-puplesija tal-qtugħ

● Kontroll preċiż tal-angolu tal-qtugħ

●kontroll preċiż tat-tneħħija tax-xfafar

●kontroll preċiż tan-numru ta' impjiegi.

3. Jadotta s-sistema idrawlika integrata BOSCH tal-Ġermanja:

● biex tissimplifika l-proċess

●biex tevita t-tnixxija taż-żejt

● biex tittejjeb l-istabbiltà tax-xogħol

● biex isebbħu d-dehra tal-magna

1. użat għall-kontroll awtomatiku tal-magna tal-qtugħ b'tmigħ minn quddiem jew backgauge funzjonali sħiħ

2. jadotta wiri LCD ta' definizzjoni għolja, programmazzjoni tat-tip tal-menù;

3. angolu tal-qtugħ, vojt tax-xafra, kalkolu u kontroll awtomatiku tal-puplesija tal-qtugħ;

4. kostruzzjoni modulari, definizzjoni flessibbli jew kontroll tal-għalf sinkronizzat X1-X2 estiż u kontroll awżiljarju tal-assi Z;

5. jadotta programmazzjoni ta' pożizzjoni assoluta u pożizzjoni relattiva;

6. tiftix awtomatiku tal-punt ta' referenza, u l-pożizzjoni mitfija tal-memorja tista' tiġi ssettjata;

7. disinn uniku tar-rota tal-idejn biex l-aġġustament tal-magna jsir b'mod konvenjenti;

8. Interfaċċja tas-serje RS232;

9. ħruġ ta' sinjali awżiljarji definiti minn diversi utenti;

10. programm ta’ awtodijanjosi;

11. ħażna interna ta' 100 linja ta' programm;

12. LCD ta' definizzjoni għolja ta' 4.7 pulzieri;

13. funzjoni tal-għadd tal-programmi;

14. għażla tal-unità tad-daqs bejn is-sistema metrika u s-sistema Ingliża.

| Le. | Oġġett | Kwantità. | Rimarka |

| 1 | Fajls tal-Magni | Sett wieħed | |

| 2 | Spanner tas-Sokit Eżagonali | Sett wieħed | |

| 3 | Pistola tal-Griż | Wieħed le. | |

| 4 | Bolt tal-Ertjar | Sett wieħed | |

| 5 | Bolt ta' Aġġustament | Sett wieħed | |

| 6 | Kontroll tas-Saqajn | Wieħed le. |

1. Sors tal-arja: kun żgur li l-pressjoni tal-gass fornuta lill-magna għandha tkun aktar minn 0.6 Mpa, il-fluss tal-gass għandu jkun aktar minn 0.3 m3/min.

2. Żejt idrawliku: żejt idrawliku kontra l-użu VG46# importat. Il-massa taż-żejt meħtieġa hija stabbilita hawn taħt:

| Mudell tal-Magna | Massa taż-Żejt (L) |

| Serje VR6, VR8 | 230 |

| Serje VRZ | 690 |

| Serje VR10 | 370 |

| VR13*3200 | 460 |

| VR13*6200 | 800 |

3. Qawwa: 380V, 50HZ, varjazzjoni fil-vultaġġ ±10%

4. Temperatura ambjentali: 0°C - +40°C

5. Umdità ambjentali: umdità relattiva 20-80% RH (mingħajr kondensazzjoni)

6. Żomm 'il bogħod mis-sors ta' vibrazzjoni qawwija u l-interferenza elettromanjetika

7. Ftit trab, l-ebda gass ta' ħsara jew korrużiv

8. Ipprepara l-pedament skont it-tpinġija tal-pedament

9. Agħżel il-persunal relattiv b'ċertu sfond edukattiv għal arranġament fit-tul bħala operatur tal-magna.

Magna tal-Qtugħ CNC; shear idrawliku tal-giljottina; magna tal-qtugħ; shearing cnc

2500

| Deskrizzjoni | Unità | 6*2500 | |

| Ħxuna tat-tqattigħ (mm) | Azzar Ħafif 450Mpa | mm | 0.5-6 |

| Azzar li ma jissaddadx 600Mpa | 0.5-4 | ||

| Aluminju 300Mpa | 0.5-8 | ||

| Tul tal-Qtugħ | mm | 2500 | |

| Angolu tat-tqattigħ | ° | 0.5°~2° | |

| Lura- gauge | Puplesija mm | mm | 5~1000 |

| Veloċità mm/s | mm/s | ≤250 | |

| Preċiżjoni mm | mm | ±0.1 | |

| Qawwa tal-Mutur Servo KW | KW | 1 | |

| Ħinijiet ta' Puplesija | hpm | 25-36 | |

| Kapaċità taċ-Ċilindru (L) | L | 230 | |

| Numru ta' Ikklampjar | le. | 12 | |

| Qawwa tal-Mutur Prinċipali (KW) | KW | 11 | |

| Sistema CNC | Sistema CNC Holland Delem DAC360 li tikkontrolla l-angolu tal-qtugħ, id-distakk tax-xfafar, u l-puplesija tal-qtugħ | ||

| Numru u tul tad-driegħ ta' appoġġ (mm) | mm | 3*1400 | |

| Dimensjoni tal-Kontorn | Tul (mm) | mm | 3110 |

| Wisa' (mm) | mm | 3000 | |

| Għoli (mm) | mm | 1705 | |

3000/3200

| Deskrizzjoni | Unità | 6*3000 | 8*3000 | 10*3000 | 13*3200 | 16*3200 | ||||

| Ħxuna tat-tqattigħ (mm) | Azzar Ħafif 450Mpa | mm | 0.5-6 | 0.8-8 | 0.8-10 | 1-13 | 1-16 | |||

| Azzar li ma jissaddadx 600Mpa | 0.5-4 | 0.8-5 | 0.8-7 | 1-8 | 1-10 | |||||

| Aluminju 300Mpa | 0.5-8 | 0.8-10 | 0.8-12 | 1-18 | 1-20 | |||||

| Tul tal-Qtugħ | mm | 3070 | 3070 | 3070 | 3200 | 3200 | ||||

| Angolu tat-tqattigħ | ° | 0.5°-2° | 0.5°-2° | 0.5°-2° | 0.5°-2° | 0.5°-2° | ||||

| Lura- gauge | Puplesija mm | mm | 5~1000 | 5~1000 | 5~1000 | 5-1000 | 5-1000 | |||

| Veloċità mm/s | mm/s | ≤250 | ≤250 | ≤250 | 200 | 200 | ||||

| Preċiżjoni mm | mm | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ||||

| Qawwa tal-Mutur Servo KW | KW | 1 | 1 | 1 | 1.0 | 1.0 | ||||

| Ħinijiet ta' Puplesija | hpm | 22-35 | 16-34 | 15-32 | 10-15 | 9-16 | ||||

| Kapaċità taċ-Ċilindru (L) | L | 230 | 230 | 370 | 460 | 460 | ||||

| Numru ta' Ikklampjar | le. | 14 | 14 | 14 | 15 | 15 | ||||

| Qawwa tal-Mutur Prinċipali (KW) | KW | 11 | 15 | 22 | 30 | 37 | ||||

| Sistema CNC | Sistema CNC Holland Delem DAC360 li tikkontrolla l-angolu tal-qtugħ, id-distakk tax-xfafar, u l-puplesija tal-qtugħ | |||||||||

| Numru u tul tad-driegħ ta' appoġġ (mm) | mm | 3*1400 | 3*1400 | 3*1400 | 3*1000 | 3*1000 | ||||

| Dimensjoni tal-Kontorn | Tul (mm) | mm | 3610 | 3640 | 3720 | 4075 | 4300 | |||

| Wisa' (mm) | mm | 3000 | 3000 | 3040 | 2752 | 3000 | ||||

| Għoli (mm) | mm | 1705 | 1755 | 1880 | 2432 | 2850 | ||||

4000

| Deskrizzjoni | Unità | 6*4000 | 8*4000 | 10*4000 | 13*4000 | 16*4000 | ||||||

| Ħxuna tat-tqattigħ (mm) | Azzar Ħafif 450Mpa | mm | 0.5-6 | 0.8-8 | 0.8-10 | 1-13 | 1-16 | |||||

| Azzar li ma jissaddadx 600Mpa | 0.5-4 | 0.8-5 | 0.8-7 | 1-8 | 1-10 | |||||||

| Aluminju 300Mpa | 0.5-8 | 0.8-10 | 0.8-12 | 1-18 | 1-20 | |||||||

| Tul tal-Qtugħ | mm | 4070 | 4070 | 4070 | 4000 | 4000 | ||||||

| Angolu tat-tqattigħ | ° | 0.5°~2° | 0.5°~2° | 0.5°~2° | 0.5°~2.5° | 0.5°~2.5° | ||||||

| Lura- gauge | Puplesija mm | mm | 5~1000 | 5~1000 | 5~1000 | 5-1000 | 5-1000 | |||||

| Veloċità mm/s | mm/s | ≤250 | ≤250 | ≤250 | ≤200 | ≤200 | ||||||

| Preċiżjoni mm | mm | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ||||||

| Qawwa tal-Mutur Servo KW | KW | 1 | 1 | 1 | 1.0 | 1.0 | ||||||

| Ħinijiet ta' Puplesija | hpm | 16~34 | 14~32 | 12~32 | 10-15 | 8-15 | ||||||

| Kapaċità taċ-Ċilindru (L) | L | 230 | 230 | 370 | 460 | 460 | ||||||

| Numru ta' Ikklampjar | le. | 18 | 18 | 18 | 19 | 19 | ||||||

| Qawwa tal-Mutur Prinċipali (KW) | KW | 11 | 15 | 22 | 30 | 37 | ||||||

| Sistema CNC | Sistema CNC Holland Delem DAC360 li tikkontrolla l-angolu tal-qtugħ, id-distakk tax-xfafar, u l-puplesija tal-qtugħ | |||||||||||

| Numru u tul tad-driegħ ta' appoġġ (mm) | mm | 4*1400 | 4*1400 | 4*1400 | 4*1000 | 4*1000 | ||||||

| Dimensjoni tal-Kontorn | Tul (mm) | mm | 4610 | 4640 | 4720 | 4970 | 5300 | |||||

| Wisa' (mm) | mm | 3000 | 3000 | 3040 | 2760 | 3000 | ||||||

| Għoli (mm) | mm | 1705 | 1705 | 1880 | 2562 | 2850 | ||||||

6000/6200

| Deskrizzjoni | Unità | 6*6000 | 8*6000 | 13*6200 | 16*6000 | 16*6200 | |||

| Ħxuna tat-tqattigħ (mm) | Azzar Ħafif 450Mpa | mm | 0.5~6 | 0.8~8 | 1-13 | 1-16 | 1-16 | ||

| Azzar li ma jissaddadx 600Mpa | 0.5~4 | 0.8~5 | 1-8 | 1-10 | 1-10 | ||||

| Aluminju 300Mpa | 0.5~8 | 0.8~10 | 1-18 | 1-20 | 1-20 | ||||

| Tul tal-Qtugħ | mm | 6140 | 6140 | 6200 | 6000 | 6200 | |||

| Angolu tat-tqattigħ | ° | 0.5˚-2˚ | 0.5˚-2.5˚ | 0.5˚-2.5˚ | 0.5˚-2.5˚ | 0.5˚-2˚ | |||

| Lura- gauge | Puplesija mm | mm | 5-1000 | 5-1000 | 5-1000 | 5-1000 | 5-1000 | ||

| Veloċità mm/s | mm/s | 200 | 200 | 200 | 200 | 200 | |||

| Preċiżjoni mm | mm | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | |||

| Qawwa tal-Mutur Servo KW | KW | 1.0 | 1.0 | 1.0 | 1.5 | 2.0 | |||

| Ħinijiet ta' Puplesija | hpm | 12~20 | 12~20 | 6-10 | 5-9 | 5-9 | |||

| Kapaċità taċ-Ċilindru (L) | L | 690 | 690 | 800 | 800 | 800 | |||

| Numru ta' Ikklampjar | le. | 29 | 29 | 27 | 27 | 27 | |||

| Qawwa tal-Mutur Prinċipali (KW) | KW | 11 | 15 | 30 | 37 | 37 | |||

| Sistema CNC | Sistema CNC Holland Delem DAC360 li tikkontrolla l-angolu tal-qtugħ, id-distakk tax-xfafar, u l-puplesija tal-qtugħ | ||||||||

| Numru u tul tad-driegħ ta' appoġġ (mm) | mm | 6*1000 | 6*1000 | 6*1000 | 6*1000 | 6*1000 | |||

| Dimensjoni tal-Kontorn | Tul (mm) | mm | 7055 | 7115 | 7220 | 7300 | 7500 | ||

| Wisa' (mm) | mm | 2686 | 2690 | 2945 | 3000 | 3000 | |||

| Għoli (mm) | mm | 2495 | 2680 | 2850 | 2850 | 2850 | |||

Serje VR (Z):

| Le. | Isem | Mudell | Marka |

| 1 | Sistema CNC | Sistema CNC DAC360 | Holland Delem |

| 2 | Mutur Servo | EMJ-10APB22 | Estun |

| 3 | Sewwieq tas-Servo | RONET-E-10A-AMA | Estun |

| 4 | Sistema Idrawlika | Sett ta' valv idrawliku elettro-servo | Bosch-Rexroth tal-Ġermanja |

| valv tal-pressjoni proporzjonali | |||

| b.valv tal-iskartoċċ | |||

| c.valv selettur elettromanjetiku | |||

| d. valv tal-pressjoni overlay | |||

| e.valv ta' kontroll idrawliku f'direzzjoni waħda | |||

| valv tat-throttle | |||

| e.valv f'direzzjoni waħda eċċ. | |||

| 5 | Gwida lineari | HSR25A-1240L | THK jew PMI |

| 6 | Ballscrew | 25/20-1400mm | THK jew PMI |

| 7 | Pompa taż-żejt | IPH-5B-50-11 jew PGH4-3X/050-E11VU2 | Pompa NACHI tal-Ġappun jew Rexroth tal-Ġermanja |

| 8 | Sett komplut ta' ċirku tas-siġillar fiċ-ċilindru taż-żejt | PARKER tal-Istati Uniti | PARKER tal-Istati Uniti |

| 9 | Sett komplut ta' pajpijiet bi pressjoni għolja | 1.F372C91C161608-1200mm | Ġonta tal-pajpijiet PARKER tal-Istati Uniti, EO-2 jew ġonta tal-pajpijiet VOSS tal-Ġermanja |

| 2.F372C91C161608-1950mm (2950mm) | |||

| 3.F381CACF151508-1480mm | |||

| 4.F381CFCF151508-2140mm (3140mm) | |||

| 5.F451TCACF121206-1600mm | |||

| 6.F3720C19201612-1300mm Jew F3720C1C202512-1300mm | |||

| 7.GE12ZLREDCF | |||

| 8.GE16SREDOMDCF | |||

| 9.GE42ZLREDCF eċċ. | |||

| 10 | Igganċjar | R38 25.385/42 eċċ. | KTR tal-Ġermanja |

| 11 | Kuntattur tal-AC | LC1-D38B7C、LC1-D25B7Ceċċ. | Schneider |

| 12 | Swiċċ tal-prossimità | TP-SM5P2 eċċ. | TEND |

| 13 | Ċomb tat-terminal | TB2.5B TB16ICH eċċ. | Feniċi |

| 14 | Buttuna | XB2-BVB3LC eċċ. | Schneider |

| 15 | Pittura | KAILEDI |

Serje VR (Z):

| Le. | Isem | Mudell | Marka |

| 1 | Sistema CNC | Sistema CNC DAC360 | Holland Delem |

| 2 | Mutur Servo | EMJ-10APB22 | Estun |

| 3 | Sewwieq tas-Servo | RONET-E-10A-AMA | Estun |

| 4 | Sistema Idrawlika | Sett ta' valv idrawliku elettro-servo | Bosch-Rexroth tal-Ġermanja |

| valv tal-pressjoni proporzjonali | |||

| b.valv tal-iskartoċċ | |||

| c.valv selettur elettromanjetiku | |||

| d. valv tal-pressjoni overlay | |||

| e.valv ta' kontroll idrawliku f'direzzjoni waħda | |||

| valv tat-throttle | |||

| e.valv f'direzzjoni waħda eċċ. | |||

| 5 | Gwida lineari | HSR25A-1240L | THK jew PMI |

| 6 | Ballscrew | 25/20-1400mm | THK jew PMI |

| 7 | Pompa taż-żejt | IPH-5B-50-11 jew PGH4-3X/050-E11VU2 | Pompa NACHI tal-Ġappun jew Rexroth tal-Ġermanja |

| 8 | Sett komplut ta' ċirku tas-siġillar fiċ-ċilindru taż-żejt | PARKER tal-Istati Uniti | PARKER tal-Istati Uniti |

| 9 | Sett komplut ta' pajpijiet bi pressjoni għolja | 1.F372C91C161608-1200mm | Ġonta tal-pajpijiet PARKER tal-Istati Uniti, EO-2 jew ġonta tal-pajpijiet VOSS tal-Ġermanja |

| 2.F372C91C161608-1950mm (2950mm) | |||

| 3.F381CACF151508-1480mm | |||

| 4.F381CFCF151508-2140mm (3140mm) | |||

| 5.F451TCACF121206-1600mm | |||

| 6.F3720C19201612-1300mm Jew F3720C1C202512-1300mm | |||

| 7.GE12ZLREDCF | |||

| 8.GE16SREDOMDCF | |||

| 9.GE42ZLREDCF eċċ. | |||

| 10 | Igganċjar | R38 25.385/42 eċċ. | KTR tal-Ġermanja |

| 11 | Kuntattur tal-AC | LC1-D38B7C、LC1-D25B7Ceċċ. | Schneider |

| 12 | Swiċċ tal-prossimità | TP-SM5P2 eċċ. | TEND |

| 13 | Ċomb tat-terminal | TB2.5B TB16ICH eċċ. | Feniċi |

| 14 | Buttuna | XB2-BVB3LC eċċ. | Schneider |

| 15 | Pittura | KAILEDI |